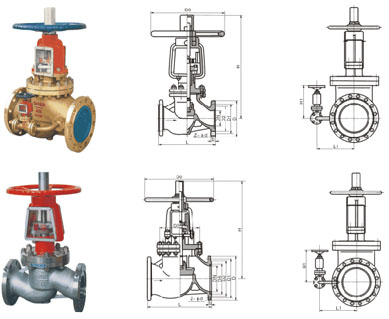

Oxygen shut-off valve

[Use of the product]

JY41W and JY41Y oxygen special shut-off valves are made of silicon brass or stainless steel with excellent materials, which have the advantages of high mechanical strength, wear resistance and good safety. Used in oxygen pipelines, it has the best explosion-proof and flame retardant properties, eliminating unsafe factors in oxygen pipelines.

[Product Features]

1. Flame-proof and fire-retardant: The main components are made of copper alloy, which is a non-combustible material. Even if it collides with solid particles in high-speed airflow, it will not produce sparks. Therefore, this valve has the best fireproof and fireproof performance.

2. Safe and reliable: This valve is equipped with dustproof, waterproof and oil-proof devices. All valves in contact with oxygen are subjected to strict degreasing and oil-free measures before assembly. The packing material is polytetrafluoroethylene, which can ensure safety and reliability in use.

Products and services that meet fluid control requirements

Each process, each facility, and each environmental constraint has its own special requirements. Therefore, Dongyan offers a comprehensive range of products covering different performance levels, pressures, different functions and different materials.

Contact

Contact Download

Download

Download

Download