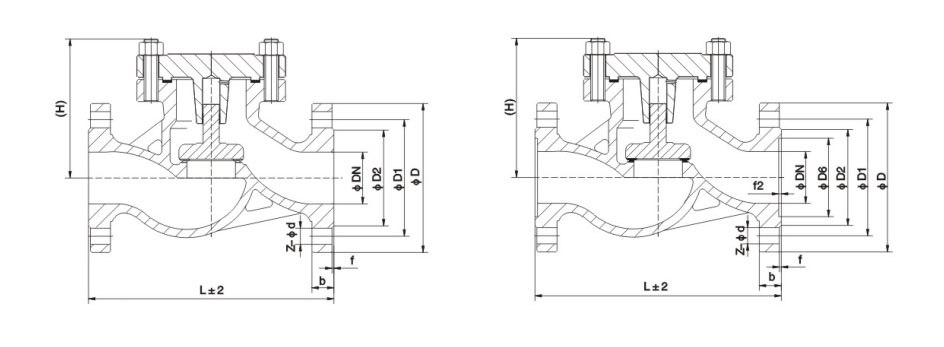

National standard lift check valve

[Product use]

H41H and H41Y type PN16~PN100 lift check valves are one of the important links in the production process regulation system. They are valves that control the one-way flow direction of the media in the pipeline and prevent the media from flow backflow.

[Product Features]

1. H41H and H41Y lifting check valves have the advantages of simple structure, reliable operation and convenient maintenance. They are widely used in purification equipment, petroleum, chemical, metallurgy, electric power, light textile and other production processes.

2. When the medium flows into the valve body by the arrow of the valve body, the pressure of the medium acts on the disc to generate upward thrust. When the medium thrust is greater than the disc gravity, the valve opens. When the force of the backward medium acting on the disc plus the force of the disc itself is greater than the force on the front pressure on the disc, the valve is closed to prevent the medium from flowing back.

Products and services that meet fluid control requirements

Each process, each facility, and each environmental constraint has its own special requirements. Therefore, Dongyan offers a comprehensive range of products covering different performance levels, pressures, different functions and different materials.

Contact

Contact Download

Download

Download

Download