[Principle of natural gas]

The closing part of the natural gas ball valve is a sphere. The ball rotates around the center line of the valve body to open and close a valve. The ball valve is mainly used in the pipeline to cut off, distribute and change the flow direction of the medium.

The floating ball valve adopts a specially designed double-bevel elastic sealing ring, which effectively reduces the friction between the sphere and the sealing ring and reduces the operating torque. When the medium pressure is small, the contact area between the sealing ring and the sphere is small, so there is a large sealing specific pressure to ensure reliable sealing. When the medium pressure is high, the contact area between the sealing ring and the drubite increases accordingly. Therefore, the sealing ring can withstand a large medium thrust without damage, ensuring a reliable seal.

[Characteristics of natural gas principle]

[Design Features]

1. Operation is labor-saving: the ball is supported by upper and lower bearings, which reduces friction and eliminates the excessive torque caused by the huge sealing load formed by the imported pressure driving the ball and the sealing seat.

2. Reliable sealing performance: The PTFE single-material sealing ring is embedded in the stainless steel valve seat, and the tail end of the metal valve seat is equipped with a spring to ensure sufficient preloading force. When the sealing surface of the valve is worn during use, the valve continues to ensure good sealing performance under the action of the spring.

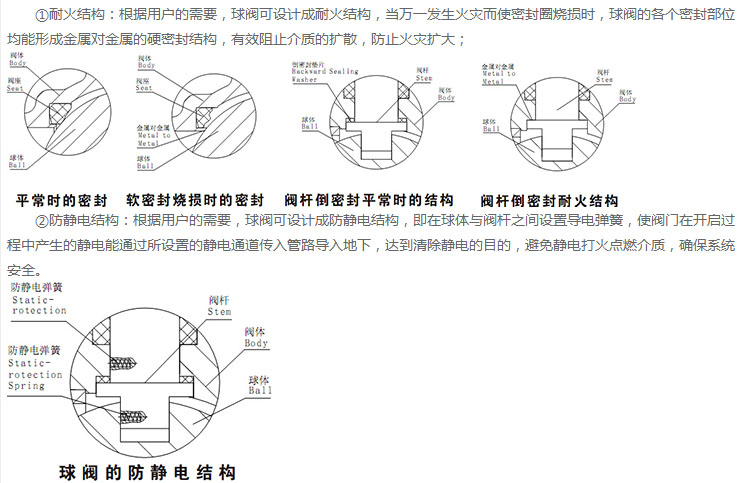

3. Fire-proof structure: In order to prevent the PTFE sealing ring from burning and causing a large leakage due to sudden heat or fire, and to promote the fire, a fireproof sealing ring is set up between the sphere and the valve seat. When the sealing ring is burned, under the action of spring force, the valve seat sealing ring is quickly pushed to the sphere to form a metal and metal seal, which has a certain degree of sealing effect. The fire resistance test meets the requirements of APl6FA and APl607 standards.

4. Automatic pressure relief function: When the medium pressure in the cavity in the valve is abnormally increased and exceeds the pre-force of the spring, the valve seat retreats from the ball to achieve the effect of automatic pressure relief. After the pressure is discharged, the valve seat is automatically restored.

5. Excretion pipeline: Excretion holes are set on the top and bottom of the valve body to check whether there is leakage in the valve seat. At work, when the valve is fully open or fully closed, the pressure of the middle cavity is removed, and the filler can be directly replaced; the retention of the middle cavity can be discharged to reduce the pollution of the valve by the medium.

Performance Parameters

Work pressure(MPa) | 1.6~25.0 |

Applicable temperature(℃) | ≤180 |

Applicable medium | Natural gas, liquefied gas |

Material | Valve body, valve cover | Carbon steel cast steel |

Sphere, valve stem | Chromium nickel molybdenum stainless steel |

Sealing ring | Polytetrafluoroethylene |

Packing material | Polytetrafluoroethylene |

Main connection dimensions

PN | DN | L | D | K | d | Y | b | Z-d0 | Ws | Hs | Hw | Hd |

1.6MPa | 40 | 165 | 145 | 110 | 85 | - | 16 | 4-18 | 230 | 135 | - | - |

50 | 203 | 160 | 125 | 100 | - | 16 | 4-18 | 260 | 150 | - | - |

65 | 222 | 180 | 145 | 120 | - | 18 | 4-18 | 350 | 180 | - | - |

80 | 241 | 195 | 160 | 135 | - | 20 | 8-18 | 500 | 195 | - | - |

100 | 305 | 215 | 180 | 155 | - | 20 | 8-18 | 650 | 245 | 310 | 420 |

125 | 356 | 245 | 210 | 185 | - | 22 | 8-18 | 800 | 270 | 330 | 440 |

150 | 394 | 280 | 240 | 210 | - | 24 | 8-23 | 1000 | 295 | 390 | 470 |

200 | 457 | 335 | 295 | 265 | - | 26 | 12-23 | - | - | 440 | 510 |

250 | 533 | 405 | 355 | 320 | - | 30 | 12-25 | - | - | 490 | 560 |

300 | 610 | 460 | 410 | 375 | - | 30 | 12-25 | - | - | 530 | 600 |

350 | 686 | 520 | 470 | 435 | - | 34 | 16-25 | - | - | 620 | 670 |

400 | 762 | 580 | 525 | 485 | - | 36 | 16-30 | - | - | 675 | 720 |

450 | 864 | 640 | 585 | 545 | - | 40 | 20-30 | - | - | 740 | 790 |

500 | 914 | 705 | 650 | 608 | - | 44 | 20-34 | - | - | 825 | 870 |

600 | 1067 | 840 | 770 | 718 | - | 48 | 20-41 | - | - | 920 | 960 |

2.5MPa | 40 | 190 | 145 | 110 | 85 | - | 18 | 4-18 | 230 | 135 | - | - |

50 | 216 | 160 | 125 | 100 | - | 20 | 4-18 | 260 | 150 | - | - |

65 | 241 | 180 | 145 | 120 | - | 22 | 8-18 | 350 | 180 | - | - |

80 | 283 | 195 | 160 | 135 | - | 22 | 8-18 | 500 | 195 | - | - |

100 | 305 | 230 | 190 | 160 | - | 24 | 8-23 | 650 | 245 | 310 | 420 |

125 | 381 | 270 | 220 | 188 | - | 28 | 8-25 | 800 | 270 | 330 | 440 |

150 | 403 | 300 | 250 | 218 | - | 30 | 8-25 | 1000 | 295 | 390 | 470 |

200 | 502 | 360 | 310 | 278 | - | 34 | 12-25 | - | - | 440 | 510 |

250 | 568 | 425 | 370 | 332 | - | 36 | 12-30 | - | - | 490 | 560 |

300 | 648 | 485 | 430 | 390 | - | 40 | 16-30 | - | - | 530 | 600 |

350 | 762 | 550 | 490 | 448 | - | 44 | 16-34 | - | - | 620 | 670 |

400 | 838 | 610 | 550 | 505 | - | 48 | 16-34 | - | - | 675 | 720 |

450 | 914 | 660 | 600 | 555 | - | 50 | 20-34 | - | - | 740 | 790 |

500 | 991 | 730 | 660 | 610 | - | 52 | 20-41 | - | - | 825 | 870 |

600 | 1143 | 840 | 770 | 718 | - | 56 | 20-41 | - | - | 920 | 960 |

4.0MPa | 40 | 190 | 145 | 110 | 85 | 76 | 18 | 4-18 | 230 | 135 | - | - |

50 | 216 | 160 | 125 | 100 | 88 | 20 | 4-18 | 260 | 150 | - | - |

65 | 241 | 180 | 145 | 120 | 110 | 22 | 8-18 | 350 | 180 | - | - |

80 | 283 | 195 | 160 | 135 | 121 | 22 | 8-18 | 500 | 195 | - | - |

100 | 305 | 230 | 190 | 160 | 150 | 24 | 8-23 | 800 | 250 | 320 | 430 |

125 | 381 | 270 | 220 | 188 | 176 | 28 | 8-25 | 1000 | 280 | 340 | 450 |

150 | 403 | 300 | 250 | 218 | 204 | 30 | 8-25 | 1200 | 300 | 405 | 480 |

200 | 502 | 375 | 320 | 282 | 260 | 38 | 12-30 | - | - | 450 | 530 |

250 | 568 | 445 | 385 | 345 | 313 | 42 | 12-34 | - | - | 505 | 590 |

300 | 648 | 510 | 450 | 408 | 364 | 46 | 16-34 | - | - | 545 | 620 |

350 | 762 | 570 | 510 | 465 | 422 | 52 | 16-34 | - | - | 640 | 690 |

400 | 838 | 655 | 585 | 535 | 474 | 58 | 16-41 | - | - | 690 | 740 |

450 | 914 | 680 | 610 | 560 | 524 | 60 | 20-41 | - | - | 760 | 810 |

500 | 991 | 755 | 670 | 612 | 576 | 62 | 20-48 | - | - | 850 | 900 |

6.4MPa | 40 | 241 | 165 | 125 | 95 | 76 | 24 | 4-23 | 260 | 140 | - | - |

50 | 292 | 175 | 135 | 105 | 88 | 26 | 4-23 | 260 | 160 | - | - |

65 | 330 | 200 | 160 | 130 | 110 | 28 | 8-23 | 350 | 180 | - | - |

80 | 356 | 210 | 170 | 140 | 121 | 30 | 8-23 | 500 | 220 | - | - |

100 | 406 | 250 | 200 | 168 | 150 | 32 | 8-25 | 800 | 250 | 320 | 430 |

125 | 450 | 295 | 240 | 202 | 176 | 36 | 8-30 | 1000 | 295 | 340 | 450 |

150 | 495 | 340 | 280 | 240 | 204 | 38 | 8-34 | 1200 | 340 | 405 | 480 |

200 | 597 | 405 | 345 | 300 | 260 | 44 | 12-34 | - | - | 450 | 530 |

250 | 673 | 470 | 400 | 352 | 313 | 48 | 12-41 | - | - | 505 | 590 |

300 | 762 | 530 | 460 | 412 | 364 | 54 | 16-41 | - | - | 545 | 620 |

350 | 826 | 595 | 525 | 475 | 422 | 60 | 16-41 | - | - | 640 | 690 |

400 | 902 | 670 | 585 | 525 | 474 | 66 | 16-48 | - | - | 690 | 740 |

500 | 1054 | 800 | 705 | 640 | 576 | 70 | 20-54 | - | - | 760 | 810 |

10.0MPa | 40 | 241 | 165 | 125 | 95 | 76 | 26 | 4-23 | 260 | 160 | - | - |

50 | 292 | 195 | 145 | 112 | 88 | 28 | 4-25 | 350 | 180 | - | - |

65 | 330 | 220 | 170 | 138 | 110 | 32 | 8-25 | 500 | 200 | - | - |

80 | 356 | 230 | 180 | 148 | 121 | 34 | 8-25 | 800 | 240 | 310 | 410 |

100 | 432 | 265 | 210 | 172 | 150 | 38 | 8-30 | 1000 | 270 | 340 | 450 |

125 | 508 | 310 | 250 | 210 | 176 | 42 | 8-34 | 1200 | 320 | 360 | 505 |

150 | 559 | 350 | 290 | 250 | 204 | 46 | 12-34 | - | - | 425 | 555 |

200 | 660 | 430 | 360 | 312 | 260 | 54 | 12-41 | - | - | 470 | 625 |

250 | 787 | 500 | 430 | 382 | 313 | 60 | 12-41 | - | - | 525 | 645 |

300 | 838 | 585 | 500 | 442 | 364 | 70 | 16-48 | - | - | 565 | 715 |

350 | 889 | 665 | 560 | 498 | 422 | 76 | 16-54 | - | - | 670 | 770 |

400 | 991 | 715 | 620 | 558 | 474 | 80 | 16-54 | - | - | 720 | 840 |

Contact

Contact Download

Download

Download

Download