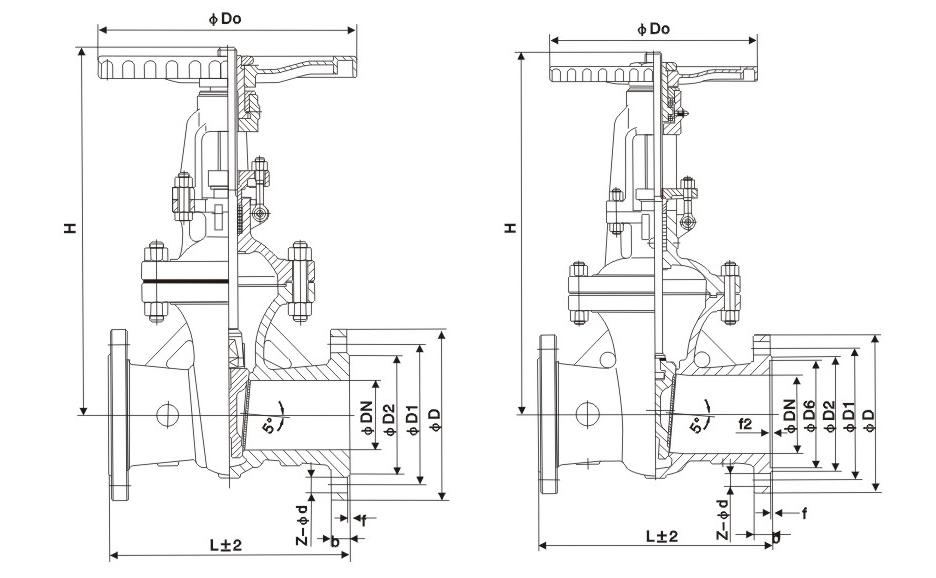

National standard flange gate valve

Stainless steel gate valves produced by the company: the valve body, valve cover, gate plate and gate rod are made of stainless steel, and the sealing surface of the valve seat is made of polytetrafluoroethylene, stainless steel + cemented carbide or welded cemented carbide. The packing material is generally made of cemented carbide, polytetrafluoroethylene, asbestos graphite or flexible graphite. Nominal size DN15~DN800, working pressure 1.6MPa~20.0MPa, applicable temperature ≤200℃, suitable for nitric acid and weak corrosive media pipelines.

[Product Features]

1. Austenitic stainless steel is used, which has good corrosion resistance to oxidizing acid media.

2. When the medium flows through the stainless steel gate valve, its flow direction does not change, and the fluid resistance is small.

3. The direction of movement of the gate is perpendicular to the direction of medium flow, the opening and closing moment is small, and the opening and closing are relatively labor-saving.

4. The direction of the medium flow is not restricted, and the pressure is not disturbed or reduced. The medium can flow from any direction on both sides of the gate valve, which can achieve the purpose of use. It is most suitable for pipelines where the direction of medium flow may change.

5. The gate plate is placed vertically in the valve body, and the structural length is relatively short.

6. Good sealing performance. When fully opened, the sealing surface is less eroded.

Products and services that meet fluid control requirements

Each process, each facility, and each environmental constraint has its own special requirements. Therefore, Dongyan offers a comprehensive range of products covering different performance levels, pressures, different functions and different materials.

Contact

Contact Download

Download

Download

Download