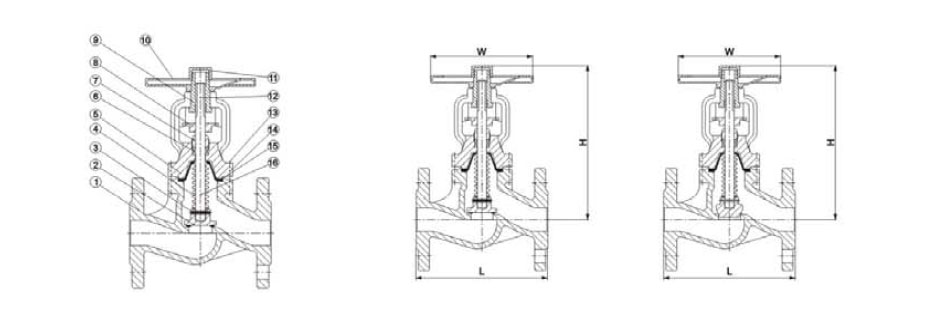

Bellows stop valve

[Product Description]

The bellows shut-off valve is suitable for cutting or connecting pipeline media in pipelines under various working conditions such as petroleum, chemical, pharmaceutical, fertilizer and power industry with nominal pressure PN1.6~PN4.0MPa and working temperature -20℃~350℃.

[Structure and Use]

1. The product structure is reasonable, the sealing performance is reliable, and the shape is beautiful;

2. Sealed surface overlay welding Co-based cemented carbide, wear-resistant, corrosion-resistant, good friction resistance and long service life;

3. Valve stem modulation and surface nitriding treatment, with good anti-corrosion and anti-friction performance;

4. The right-angled German bellows shut-off valve is double sealed, and the performance is more reliable;

5. The position indication of the valve stem lifting is more intuitive;

6. Parts material, flange and butt welding number size can be reasonably selected according to the actual working conditions or user requirements to meet various engineering needs.

Products and services that meet fluid control requirements

Each process, each facility, and each environmental constraint has its own special requirements. Therefore, Dongyan offers a comprehensive range of products covering different performance levels, pressures, different functions and different materials.

Contact

Contact Download

Download

Download

Download